October 2 webinar | Sustainability in Action: Green Chemistry for a Sustainable Future

Leider unterstützen wir Ihren Browser nicht vollständig. Wenn Sie die Möglichkeit dazu haben, nehmen Sie bitte ein Upgrade auf eine neuere Version vor oder verwenden Sie Mozilla Firefox, Microsoft Edge, Google Chrome oder Safari 14 bzw. eine neuere Version. Wenn Sie nicht dazu in der Lage sind und Unterstützung benötigen, senden Sie uns bitte Ihr Feedback.

Wir würden uns über Ihr Feedback zu diesen neuen Seiten freuen.Sagen Sie uns, was Sie denken

How sustainable chemicals and materials can drive the transition to a circular economy.

According to a global Oracle survey, 91% of business leaders are looking to invest in projects to advance their sustainability goals. It is widely understood that modern manufacturing practices negatively impact the environment and contribute to greenhouse gas emissions, groundwater contamination and energy consumption.

The manufacturing industry was the third largest contributor of greenhouse gasses in 2021, accounting for 23% of all direct emissions in the United States. At the same time, manufacturing activities accounted for 74% of the total energy consumption in the industrial sector in 2018. Organizations are rapidly looking to sustainable manufacturing in order to reduce their carbon footprint and meet crucial net-zero targets.

While the term “sustainable manufacturing” covers many different areas, these practices generally increase efficiency, reduce waste and positively impact net-zero targets with the help of renewable energy, lean manufacturing, green chemistry and other key processes.

As a decision-maker tasked with the broad goal of advancing sustainability in your organization, you have countless areas to research and even more questions to consider. For example:

How do you balance your organization’s needs with costs, investors’ expectations and consumer demand?

Which options will provide the most favorable risk-benefit ratio?

And most importantly, which changes will have the greatest impact on both your sustainability goals and your bottom line?

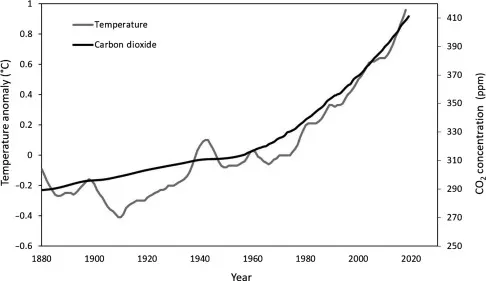

Correlation of recent temperature anomaly with CO2 rise. (Source: Reaching Net Zero: What it Takes to Solve the Global Climate Crisis)

Besides the rise of environmental regulations around the world, consumers and stakeholders also influence the need for sustainable manufacturing practices. The 2021 Global Consumer Insights Survey from PWC found that shoppers are becoming more health-conscious and eco-friendly. Investors echo this sentiment, with 78% supporting more environmental initiatives even if they affect short-term profits, according to a study by Ernst & Young. Meeting consumer and investor expectations means creating more sustainable products, which drives the need for an increase in sustainable manufacturing practices and the use of more ecologically sound materials and inputs.

Finally, manufacturing companies must ensure they stay competitive, which often begins with establishing efficient operations that evolve with the industry. Running a production facility that has double the energy demand of your competitor means charging higher prices, reducing your competitive edge within the market. Sustainable practices, process intensification and green chemistry principles help organizations produce higher-quality, competitive products while reducing waste and energy consumption.

This combination of factors is casting a spotlight on sustainability, changing the way manufacturers approach it. Sustainability is no longer an option; it’s quickly becoming a necessity to stay competitive, reduce costs, contribute to net-zero goals and build efficient operations.

Read more about unlocking circular innovation in chemicals and materials.

Green chemistry is a key driver of sustainable innovation in the chemical industry. Embracing the principles of green chemistry in manufacturing and production reduces or eliminates pollution at the source, unlike technologies and processes that target existing pollutants in the environment. These principles impact every step of the chemical manufacturing process, from design to disposal.

The 12 principles of green chemistry, originally outlined by Paul Anastas and John Warner, serve as a set of guidelines for minimizing the environmental, economic and health impacts of chemical production.

Prevention: Prevent waste generation at the source rather than cleaning it up post-production

Atomic economy: Minimize waste generation by incorporating the majority of the reagents used during the process

Safer synthesis: The chemical synthesis process should both use and generate substances with the least amount of toxic impact on the environment and human health

Safer design: The design process should aim to produce chemicals with the lowest possible toxicity potential while preserving efficacy

Safer solvents and auxiliaries: Solvents and auxiliaries should be avoided when possible or substituted with less harmful alternatives

Energy efficiency: The process should minimize energy consumption to decrease environmental and economic impacts

Renewable raw materials: Renewable feedstocks and raw materials should be emphasized over non-renewable sources whenever possible

Reduction of derivatives: Derivatives should be avoided to reduce additional steps and waste generation

Use of catalysts: Catalytic reagents should take priority over stoichiometric reagents to reduce waste and increase efficiency

Degradable design: Chemicals should be designed to degrade rather than remain in the environment

Real-time pollution monitoring: Real-time in-process monitoring should be prioritized to avoid hazardous substances

Accident prevention: Occupational safety should be considered during the process to minimize accidents

Green chemistry principles fall in line with the Sustainable Development Goals (SDGs) proposed by the United Nations, which aim to address sustainability through a lens of environmental, economic and social impacts. For example, SDG 12 focuses on sustainable consumption and production, which relates directly to several green chemistry principles such as the use of renewable raw materials and safer chemical design.

Learn more about recent chemicals industry trends, including SSbD chemicals and specialty chemicals.

12 Principles of green chemistry, from Evolution of green chemistry and its multidimensional impacts: A review (Source: Saudi Pharmaceutical Journal)

Sustainable manufacturing mirrors many of these objectives, focusing on production processes that minimize environmental harm, conserve energy, utilize natural resources and improve safety. As a result, green chemistry principles are a significant element of sustainable manufacturing.

The drive for innovation is a key motivator for the chemical industry to explore new processes, technologies and materials. Chemical manufacturers have more choices when it comes to sustainable, bio-based and green raw materials than ever before.

Read more: The key chemicals industry trends driving innovation in 2025

A key focus in sustainable manufacturing is a focus on new sustainable packaging materials. Traditional single-use plastic packaging ends up infiltrating ecosystems, seeping into our oceans and creating toxic pollutants when incinerated, decreasing the air quality and posing health risks for humans. Creating new materials requires a complete lifecycle approach to ensure every element of the process — from raw material sourcing to production and degradation — reduces environmental impact.

Biodegradable materials derived from seaweed and corn, as well as recycled and recyclable materials, are already being utilized to create alternatives to single-use plastic packaging. Coca-Cola announced that 100% of its bottles in over 25 markets are now made from recycled polyethylene terephthalate (rPET). The company is also rolling out new packaging labels encouraging consumers to recycle rPET bottles in order to reuse them and build a circular economy.

Meanwhile, U.K.-based packaging manufacturer Notpla wants to “make packaging disappear forever.” Notpla’s seaweed-based packaging containers are 100% biodegradable and non-toxic, meant to biodegrade within four to six weeks. Their product line includes drinkable pods, cartons and sachets for food packaging.

Canada-based CelluloTech is working to improve paper packaging, positioning it as a greener alternative to plastic. CelluloTech developed a cellulose alternative to plastic coatings on paper packages, making them less toxic and more environmentally friendly. The technology is called chromatogeny, a green chemistry process that removes the need for solvent use in production.

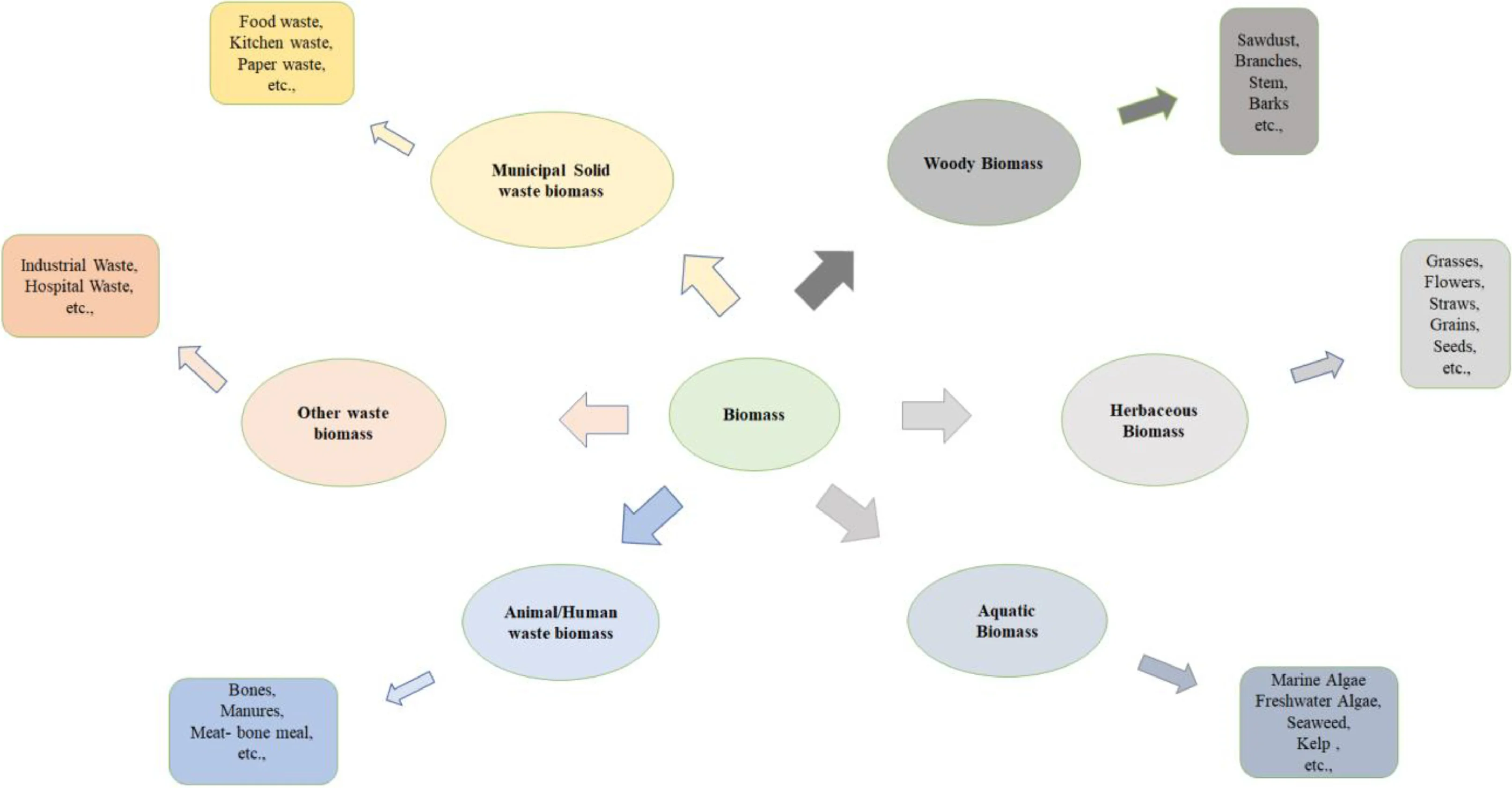

Biomass feedstocks derived from plants, animals and microorganisms serve as alternative raw materials for chemical manufacturers. These feedstocks can be sourced from agricultural residues, dedicated energy crops, forestry residues, algae and organic waste streams.

Cargill has deeply invested in biomass feedstocks, offering several different types of products made from corn, wheat, soy, or vegetable oil bases. Their plasticizers, adhesives, cooling fluids, fertilizers and more have been developed with sustainability, safety and the environment in mind.

Different classifications of biomass. (Source: A critical review of the transformation of biomass into commodity chemicals)

Pushing the idea of biomass feedstocks as a better alternative to petroleum, Princeton University researchers have published a study based on the computational analysis of 25 common chemicals. While the study shows that 24 out of the 25 chemicals could be successfully produced in a biorefinery, which could significantly contribute to greenhouse gas reduction, it is important to consider the full life cycle impacts of the bio-feedstock sources. This includes assessing the agricultural practices used to cultivate the biomass feedstocks, harvesting and processing steps, and transportation emissions. Researchers found that using bio-feedstocks for the production of these chemicals could lower manufacturing emissions between 88% and 94%. However, a comprehensive life cycle assessment is needed to validate the sustainability benefits across the complete supply chain and use phase of these bio-based chemicals.

Read more about the latest materials and compounds driving sustainable chemistry innovation.

A recent McKinsey analysis predicted that global battery demand is expected to grow by over 30% annually until 2030. With the battery industry facing raw material shortages, growing consumer demand for green technologies and stricter regulations in many European countries, the need for increased energy storage is accelerating the need for innovation.

Current research in the battery space examines the potential of elements found in abundance rather than the relatively rare lithium and cobalt that traditional rechargeable batteries utilize. Sodium-ion batteries hold strong potential as an alternative for large-scale applications, often demonstrating lower costs, improved chemical stability and safety benefits.

Although research is still ongoing, manufacturers around the world are already experimenting with the possibilities of sodium-ion batteries. Chinese battery manufacturer CATL recently announced a deal with automobile manufacturer Chery to power several EV models with their new sodium-ion batteries.

In the U.S., Natron Energy manufactures several types of sodium-ion batteries based on its patented Prussian blue electrodes technology. Natron’s batteries contain twice the power of lithium-ion batteries, operate in wide temperature ranges and are produced with ethically sourced raw materials.

Bioplastics derived from biomass sources, such as plant-based feedstocks, offer an alternative to conventional petroleum-based plastics. Designed to reduce how is the environmental impact associated with plastic production and disposal, bioplastics are either bio-based or biodegradable. Some bioplastics such as polylactic acid (PLA), polyhydroxyalkanoates (PHA) and polybutylene succinate (PBS) are both bio-based and biodegradable.

Microalgal Biorefineries for Industrial Products (Source: Microalgae Cultivation for Biofuels Production)

BASF is a key player championing digital transformation, innovation and sustainability in the manufacturing space. With a vast portfolio of products, BASF centers its strategy on sustainability, including its approach to polymers. BASF’s two bioplastic products, Ecovio and Ecoflex, are both compostable, biodegradable and either partly or fully bio-based. Other companies such as Marine Innovation and Biopac are taking a more novel approach by using algae as a feedstock for bioplastic products like food packaging and dishes. Algae-based plastics show great potential for addressing multiple challenges in polymer production, from land and water shortages to the rising cost of raw materials because of the plant’s high growth rate and adaptability.

Learn more about how Knovel supports the development of sustainable plastics.

The future of sustainable manufacturing holds great potential as industries continue to prioritize environmental responsibility and resource efficiency. Some key aspects likely to shape the future of sustainable manufacturing include:

Commitment to a circular economy: A larger focus on designing products with the intent of maximizing their lifespan, promoting reuse and repair and ensuring materials and components are recycled or repurposed at the end of their life cycle will keep materials in circulation and minimize waste generation.

Adoption of sustainable processes: Innovative manufacturing processes, supported by rapidly evolving technology, will allow for more precise and efficient use of materials, waste minimization and lower energy consumption.

Innovation in sustainable materials: Discovery of new materials with reduced environmental impact, enhanced performance and recyclability will gain greater momentum due to more efficient data analysis and technological developments.

Renewable energy integration: Greater investments in and the integration of renewable energy sources will enable efficient energy management and facilitate the use of clean energy in manufacturing processes.

Greater supply chain transparency: Increased transparency, responsible sourcing and ethical practices will improve supply chains to mitigate environmental and social risks, promoting sustainable practices from raw material extraction to product distribution.

Increased collaboration and partnerships: More open and widespread collaboration among stakeholders, including manufacturers, government agencies, research institutions and consumers, will foster knowledge exchange, resource sharing and the development of innovative solutions to complex sustainability challenges.

By adopting these approaches, chemical manufacturers can minimize environmental impact, enhance resource efficiency and contribute to a more sustainable and resilient future.

As sustainability becomes central to manufacturing strategy, chemical companies must evaluate new materials, processes and technologies through a full lifecycle lens. Turning innovative ideas into measurable success relies on trusted knowledge and tools that bring clarity and confidence to research decisions.

Elsevier helps organizations navigate this complexity with a portfolio of solutions to support and optimize innovation outcomes. Enable faster, better decision-making across R&D initiatives with:

Trusted quality information, including peer-reviewed scientific literature, domain-specific data

Innovative technology that powers data transformation and analytical and predictive tools

Domain and data science expertise to solve complex problems with data solutions for R&D

Let’s shape progress together.

Sign up for a quarterly email update from Elsevier on the latest Industry Sustainability Insights, which spotlights hot industry topics, information on upcoming webinars, new articles and other resources.