5 key carbon capture technology trends for 2023 (with examples)

24. Mai 2023

Von Bryan Davies

Recent breakthroughs could change carbon capture as we know it and help the energy industry minimize its carbon footprint.

Energy organizations have practiced enhanced oil recovery (EOR) using carbon capture since the 1960s, but recent trends and breakthroughs have accelerated the application, efficiency and affordability of carbon capture — a key component of the energy industry’s carbon reduction goals.

Carbon capture is a continually evolving field of research, enabling energy and natural resources organizations to reduce their carbon footprint, improve production processes and strive for a more sustainable economy. These five breakthroughs have the potential to change the carbon capture process on a global scale in 2023 and beyond.

1. Material developments unlock higher carbon capture potential

Carbon capture technologies are utilized by various industries on a global scale, but that doesn’t mean the systems are ideal. Ongoing research into new materials focuses on creating solutions to combat industry’s most common concerns about carbon capture, including implementation costs, energy needs and volume limitations.

Metal-organic frameworks (MOFs) are a core topic in carbon capture research because they showcase incredible possibilities for reducing carbon emissions. MOFs are highly porous solid materials “composed of a three-dimensional (3D) network of metal ions held in place by multidentate organic molecules.” They essentially act like high-absorbency sponges and can be engineered to capture specific gas molecules. Their vast surface areas allow for high-volume CO2 collection, which is promising for the development of more efficient methods of carbon capture.

Aluminum formate (ALF) is a type of MOF that may be viable for large-scale use in coal-fired power plants, according to the National Institute of Standards and Technology (NIST). Researchers found that not only does ALF perform better than other adsorbents, but the substances that form it are also more stable, easy to prepare and abundant in the market. This means that using ALF as the central material in MOF-based technologies can result in more efficient processes with greater carbon capture potential.

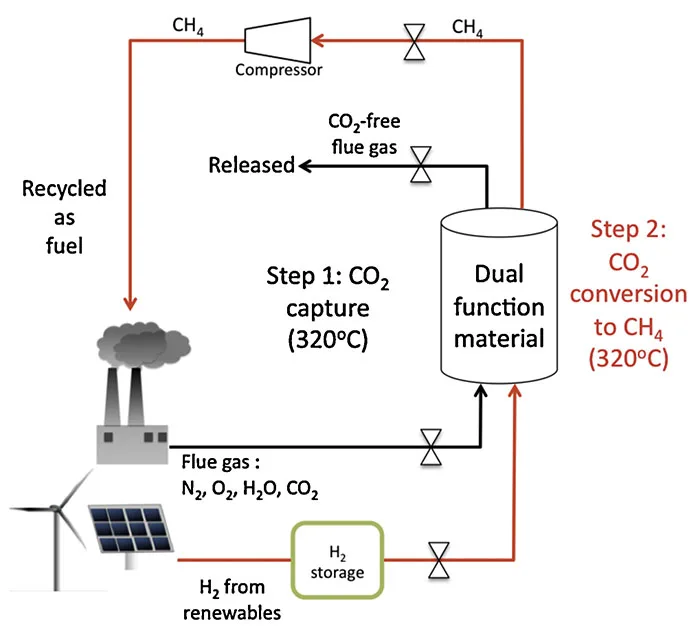

Process diagram for CO2 capture and recycle as synthetic natural gas (CH4) back to an industrial facility. (Source: Melis S Duyar et al: Dual-function materials for CO2 capture and conversion using renewable H2, Applied Catalysis B: Environmental, 2015)

The University of Surrey found another material breakthrough in its work withDual Function Materials (DFMs). DFMs contain a catalyst component and sorbent, meaning they can capture CO2 while simultaneously and “at the same temperature (320°C) in the same reactor convert it to synthetic natural gas, requiring no additional heat input.” This removes the need for additional stages like transportation and storage of CO2 after capture, as well as the energy-intensive processes required for most capture methods.

2. New methods advance Direct Air Capture projects

Direct air capture (DAC) is a promising method of carbon sequestration that removes CO2 directly from the atmosphere, creating an opportunity for massive steps toward global carbon reduction. While there are only 19 DAC facilities worldwide, the development of new capture methods is helping transition this technology into wider-scale programs.

Climeworks has become a leader in the DAC industry by combining DAC with geological storage in its partnership with CO2 storage firm Carbfix. Its modular DAC plants run on renewable or residual energy, utilize minimal land space and are adaptable to any project size. The plants pull in air through large fans, then push it through a filter that collects CO2 and releases clean air back into the environment. Once the filters are at maximum capacity, the plant is heated and the CO2 is collected to be permanently stored in geological formations. Climeworks already runs a large-scale facility, Orca, and is in the process of constructing Mammoth, a second commercial DAC facility.

Other organizations are developing unique ways of capturing CO2 directly from the atmosphere. Heirloom Carbon Technologies found a breakthrough use for limestone with its DAC method. Using CO2-deprived limestone, Heirloom mimics natural carbon mineralization at hyper-speed. While natural carbon mineralization takes years, Heirloom’s technology allows the limestone to soak up CO2 to its full capacity in three days. Carbon is then separated through a heating process and put into long-term storage or sold to Heirloom’s partner, CarbonCure, to cement. Heirloom promises the ability to remove over 1 billion tons of CO2 from the atmosphere by 2035 with its innovative technology.

3. Cost-saving technologies promise affordable carbon capture methods

The high cost of carbon capture technology is an often-cited concern for industries looking to implement large-scale projects. Estimates vary by industry, but $15-$120/t CO2 is a common range, although additional factors like transportation and storage raise the total cost. Building cost-saving technologies is currently a key focus of research in order to scale up carbon capture projects and reach carbon reduction goals.

US-based carbon solution company Global Thermostat has made breakthroughs in addressing the energy needs of DAC, as well as the cost of retrofitting facilities. DAC technology requires high levels of heat to separate CO2 emissions from the source, meaning higher costs and additional pollution. At the same time, facilities weren’t designed with DAC in mind, so retrofitting can quickly lead to skyrocketing upfront costs. Global Thermostat tackled both of these issues with a unique DAC solution that runs on residual heat and can be easily retrofitted for any existing facility at a lower cost. Global Thermostat has a close partnership with Exxon Mobil and has recently signed on to work with Japan’s Tokyo Gas to expand its reach.

The US Department of Energy’s Pacific Northwest National Laboratory (PNNL) is working to reduce carbon capture costs by targeting another key cost issue: materials. PNNL developed a capture system that uses a solvent to isolate CO2 from flue gas and convert it to methane. The process uses less heat than traditional scrubbing methods. Researchers at PNNL estimate that this unique system uses 17% less energy, leading to a 19% reduction in costs. The process also results in byproducts like methane, methanol or formate, which can be used to replenish valuable resources or sold to offset the costs of carbon capture.

UK-based MOF Technologies is pioneering the commercial use of MOFs to reduce carbon capture costs with Nuada, a unique technology that uses vacuum swing adsorption combined with a MOF-based filter. Vacuum swing adsorption is a common CO2 separation technology used across the energy industry, but the addition of MOFs makes it more efficient and cost-effective. The result is a massive 80% reduction in energy needs and almost no retrofitting costs, as the modular system is a compact and standalone structure that can be placed anywhere.

4. CCUS technologies are set to revolutionize the hydrogen economy

Experts are looking at hydrogen as a major player in decarbonization over the next decade because it has the potential to become an emission-free source of energy. According to the International Energy Agency, the current production of hydrogen emits 830 million tons of CO2 per year, but carbon capture technology is leading the way for “blue” hydrogen — a low-emission alternative.

Blue hydrogen is produced with the help of carbon capture and storage (CCS) technologies, which remove CO2 during the production process and create a source of clean energy. Compared to today’s standard methods of hydrogen production, like steam methane reforming (SMR), blue hydrogen has the potential to capture 50% to 90% of CO2 emissions.

Some of the world’s largest energy companies are launching large-scale blue hydrogen production facilities, including Exxon Mobil. The project, based in Exxon’s complex in Baytown, Texas, is set to be the largest in the world, with the ability to reduce its current CO2 emissions by 30%. Norway’s state-owned energy company Equinor has similar plans with a new facility planned in Rostock. Partnering with Germany’s VNG, Equinor’s facility will be able to separate and remove an estimated 2 million tons of CO2 from hydrogen production annually.

5. Biohybrid photocatalysts pave the way for new methods of carbon capture

Biohybrid photocatalysis is a method that mimics the natural process of photosynthesis using metal-organic frameworks (MOFs) to protect bacteria that capture CO2 and use it to produce valuable chemicals. This development displays immense potential because MOFs have extremely high surface areas, with just “one gram holding the equivalent surface area of a football field,” allowing for high-volume carbon capture.

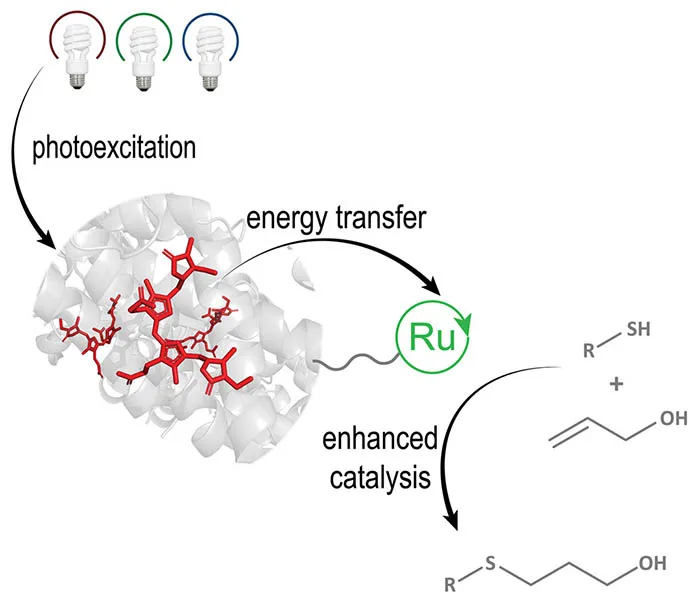

Graphical abstract (Source: Paul T Cesana et al: A biohybrid strategy for enabling photoredox catalysis with low-energy light, Chem, Jan 2022)

Researchers at the Massachusetts Institute of Technology (MIT) have developed a biohybrid photocatalyst design that reduces the amount of energy required to create a reaction. Using R-phycoerythrin (RPE), a protein typically found in red algae, the technology captures natural light for use in catalysis. The concept is still in the early research phase, but researchers believe that biohybrid photocatalysts can make “pharmaceutical, agrochemical and fuel synthesis more efficient and environmentally compatible.”

Stay on the cutting edge of carbon capture

With continuous advancements in materials and processes, the field of carbon capture is evolving quickly. Launch your carbon capture project with confidence by staying up to date with Elsevier. Connect with industry experts and get access to curated abstracts with Scopus, or dive deeper with ScienceDirect’s 1.4 million full-text peer-reviewed articles.